With several advantages over Light-Emitting Diodes (LEDs) and Edge-Emitting Lasers (EELs), Vertical Cavity Surface Emitting Lasers (VCSELs) are instrumental in many recent technological advancements, and new applications are found every day.

Testing VCSELs by manufacturers of these devices and device integrators requires optical spectrometers featuring high-resolution, high-speed triggering response and short integration time specifications. Avantes is the trusted instrument supplier around the world to support applications with VCSEL technology.

Introduction to VCSEL Structure

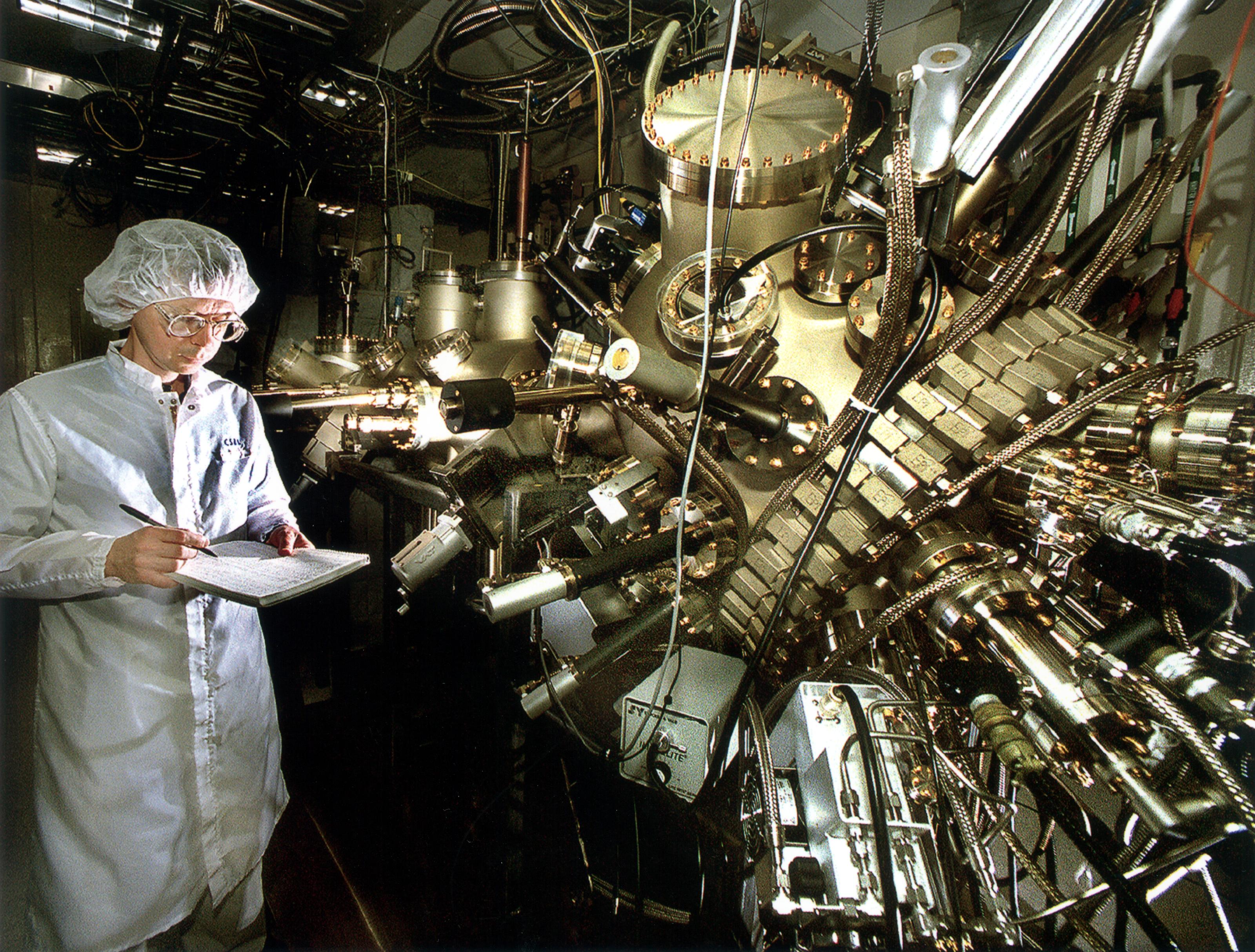

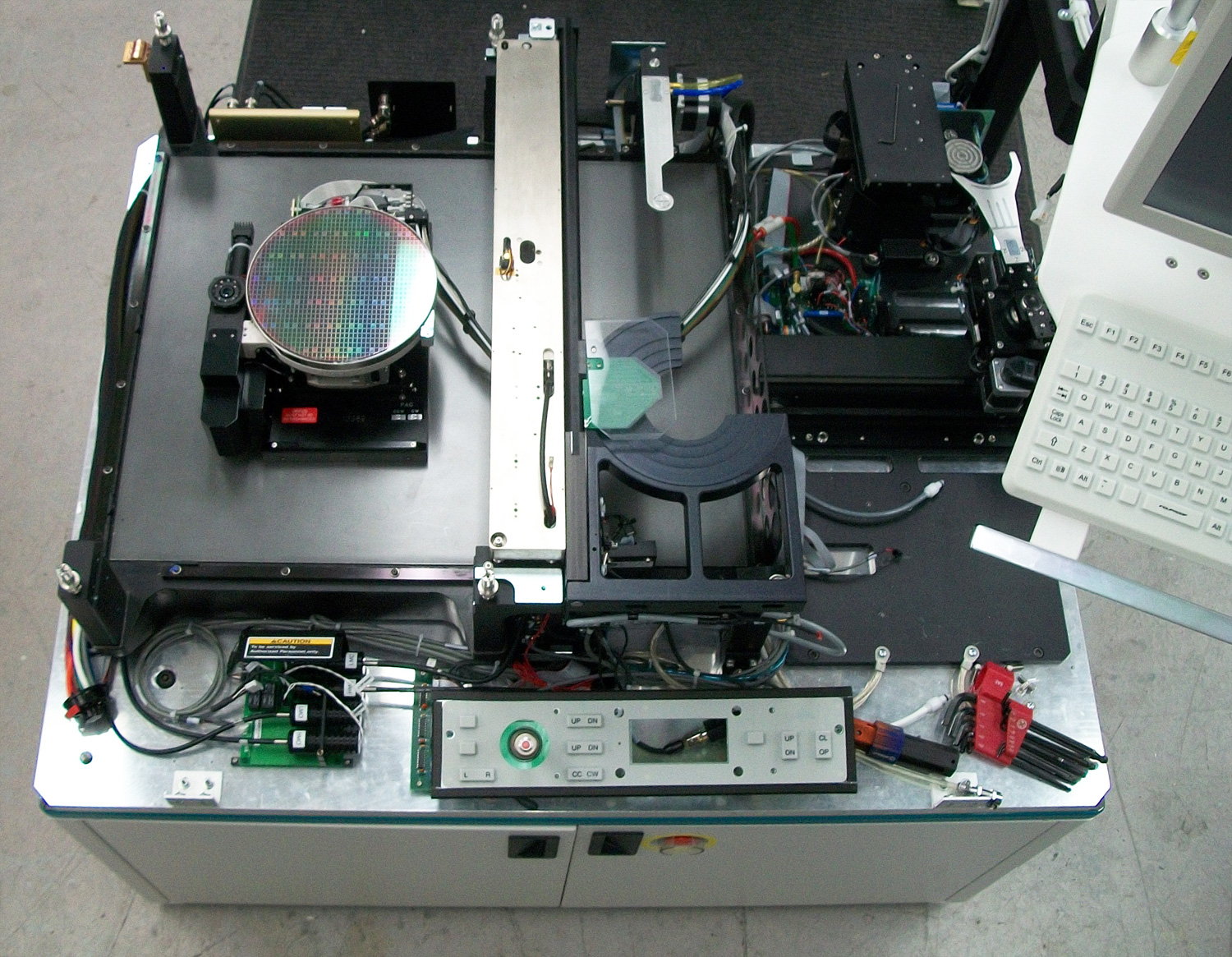

Vertical cavity surface-emitting lasers are a semiconductor-based light source grown in mass production using standard thin-film deposition techniques such as either molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD) to deposit films on Gallium Arsenide (GaAs) wafers. VCSELs emit a coherent beam of light from their surface.

The structure consists of two highly-reflective distributed Bragg reflector (DBRs) mirrors parallel to the wafer surface and made by alternating layers of high and low refractive indices capable of yielding intensity reflectivities. The DBR are typically doped to form the diode junction and used to deliver a carrier signal to stimulate emissions into the active region.

The carrier signal passes through the active laser medium which provides optical feedback and amplifies the light between the reflective matrices, inciting laser propagation, which is possible at a current where the round-trip gain is greater than the round-trip loss. Because the vertically oriented gain region of the VCSEL design is shorter than required for other semiconductor lasers, the VCSEL lasers have a low threshold current for laser propagation. The DBR with the lowest refractivity is then out-coupled for coherent light emission.

[BY Edgar Cerda Mendez], via Research Gate

The VCSEL Advantage

The vertical design of the VCSEL has several advantages over edge emitters. An edge-emitting laser cannot be tested until the deposition processes are complete and the elements are die cut from the wafer. If there are defects in the wafer or thin films, the manufacturing time and materials have been wasted. The VCSELs, on the other hand, can be mass-produced using ordinary semiconductor thin-film deposition methods in a process that can be tested at various stages of production, including whole wafer testing so that thousands of VCSELs can be processed at once on a single three-inch wafer. This leads to greater production efficiency and reduced costs (Finisar myvcsels.com).

Another benefit of the VCSEL design is the ability to connect multiple elements into two-dimensional arrays for increased power output and the larger output aperture produces a lower divergence angle of the output beam for better coupling efficiency with optical fibres.

VCSELs are capable of high-power output, yet consume less power than other lasers/light-emitting devices due to the placement of the distributed Bragg reflectors (DBRs), which lowers the threshold current to achieve laser propagation. The wavelength tuneability, which is characteristic of VCSELs, is accomplished by adjusting the thickness of the reflector layers in the active region with the aid of microelectromechanical systems.

By ENERGY.GOV [Public domain],

via Wikimedia Commons

Current Applications for VCSEL Technology

In the 40 years since VCSELs were introduced, they have found their way into countless applications across hundreds of industries and markets both industrial and commercial, and today we see VCSELs all around us. One of the key functionalities of these devices is signal processing, which might take the form of communications or sensing.

Fibre-optic communication relies heavily on the signal processing power of VCSELs emitting in the 1310 nm and 1550 nm bands, to deliver pulses of light forming an electromagnetic carrier wave that can be modulated to carry signals for telephony, cable, and internet (Larson).

One of the most ubiquitous uses for VCSELs that anyone would be immediately familiar with is the laser mouse on your computer. (VCSEL Wiki). Other examples of common VCSEL applications include laser printers, miniature atomic clocks, facial recognition in mobile devices, and collision-avoidance systems in equipped vehicles. (VCSEL Wiki).

By Quinn Dombrowski from Berkeley, USA

[CC BY-SA 2.0 ], via Wikimedia Commons

The Future of VCSELs

Research conducted by Kitsmiller, Dummer, Johnson, et al. at the University of Notre Dame’s Department of Electrical Engineering investigated the use of frequency domain diffuse optical spectroscopy (fd-DOS) employing near-infrared tuneable VCSELs to develop a miniaturized system to perform high-resolution deep tissue scans in non-invasive biomedical imaging.

Advances in non-invasive monitoring, especially wearable sensors, have been technologically constrained by the commercial availability of miniature light sources capable of producing coherent near-infrared light in the first biological diagnostic window between 650-1350 nm. Adding spectral content can increase the accuracy, spatial resolution, and sensitivity but adding additional lasers or LED components adds to the size and complexity of the system, competing with the goal of developing handheld and wearable sensors and monitoring devices.

Avantes Spectrometers in VCSEL Manufacturing and Testing

Avantes AvaSpec instruments are used by a variety of VCSEL manufacturers and integrators to test the performance of these devices. The AvaSpec-ULS3648, AvaSpec-ULS4096CL-EVO and the Mini4096CL are three spectrometers that are commonly used in VCSEL characterization. Many customers have found our instruments to be an acceptable substitute for much more costly optical spectrum analyzers (OSA) for many of their common VCSEL tests.

As many VCSELs produced today emit in the near infrared, common configurations of these instruments feature high-resolution gratings (1200 or 1800 grooves/mm) blazed in the NIR. The inherent power of the devices being measured allows for the use of 5- or 10-micron slits providing the highest resolution possible, but this can result in some levels of signal attenuation. Some of the key advantages of these instruments cited by customers include high resolution, high pixel count, easy software integration, and appropriate sensitivity to enable high-speed takt times for testing.

Avantes spectrometers are used in this application to measure a variety of typical VCSEL parameters including spectral peak wavelength, centroid, side mode suppression ratio, Full Width Half Maximum (FWHM), and RMS spectral bandwidth. As some VCSELs are operated in pulsed mode, the AvaSpec line of instruments is well suited to handle this type of source. The AS5216 USB2 electronics and AS7010 USB3/Ethernet boards are both capable of sending or receiving TTL external triggers to control the window of integration for the pulsed signal.

At the device interface, Avantes line of optical sampling accessories including cosine correctors and integrating spheres along with our fibreoptic patch cords provide for the means to collect the light emission from the VCSEL no matter the size or power of the devices.

via Wikimedia Commons

Conclusion

Avantes spectrometers offer an affordable alternative to OSAs for VCSEL testing and characterization. The high-resolution, high-sensitivity and high-speed characteristics of the AvaSpec line of spectrometers make them ideally suited for this application. Avantes’ easy to implement DLL library makes integration with production software straightforward. To discover why so many VCSEL and semiconductor manufacturers are turning to Avantes for equipment they can trust, contact your dedicated sales support engineer today.

Related Products

Related Pages

Resources

Dändliker, René. ‘Concept of modes in optics and photonics.’ Sixth International Conference on Education and Training in Optics and Photonics. Vol. 3831. International Society for Optics and Photonics, 2000.

Iga, Kenichi. ‘Surface-emitting laser – its birth and generation of new optoelectronics field.’ IEEE Journal of Selected Topics in Quantum Electronics6.6 (2000): 1201-1215.

Kitsmiller, Vincent J., et al. ‘Frequency domain diffuse optical spectroscopy with a near-infrared tuneable vertical cavity surface emitting laser.’ Optics Express 26.16 (2018): 21033-21043.

Koyama, Fumio. ‘VCSELs: their 30 years history and new challenges.’ Optoelectronic Materials and Devices III. Vol. 7135. International Society for Optics and Photonics, 2008.

Larsson, Anders. ‘Advances in VCSELs for communication and sensing.’ IEEE Journal of Selected Topics in Quantum Electronics 17.6 (2011): 1552-1567.

Michalzik, Rainer. ‘VCSELs: A Research Review.’ VCSELs. Springer, Berlin, Heidelberg, 2013. 3-18.

Wikipedia contributors. ‘Vertical-cavity surface-emitting laser.’ Wikipedia, The Free Encyclopedia. 28 Sept. 2018. Web. 10 Oct. 2018.

Wikipedia contributors. ‘Distributed Bragg reflector.’ Wikipedia, The Free Encyclopedia. 26 Sept. 2018. Web. 10 Oct. 2018.

Wikipedia contributors. ‘Quantum well’. Wikipedia, The Free Encyclopedia. Wikipedia, 6 Oct. 2018. Web. 10 Oct. 2018.

Wikipedia contributors. ‘Fibre-optic communication.’ Wikipedia, The Free Encyclopedia. Wikipedia, The Free Encyclopedia, 25 Aug. 2018. Web. 10 Oct. 2018.

‘What Is A VCSEL | VCSEL.’ Myvcsel.com. N. p., 2018. Web. 15 Oct. 2018.

‘Key Advantages Of VCSEL Technology | VCSEL.’ Myvcsel.com. N. p., 2018. Web. 15 Oct. 2018.

‘Designing With VCSELs | VCSEL.’ Myvcsel.com. N. p., 2018. Web. 15 Oct. 2018.

‘Emerging Applications | VCSEL.’ Myvcsel.com. N. p., 2018. Web. 15 Oct. 2018.

‘Modulating VCSELs’ Finisar.com. N. p., 2018. Web. 15 Oct. 2018.